Smart sensing for food quality & logistics

We don't just measure. We solve your problems with data.

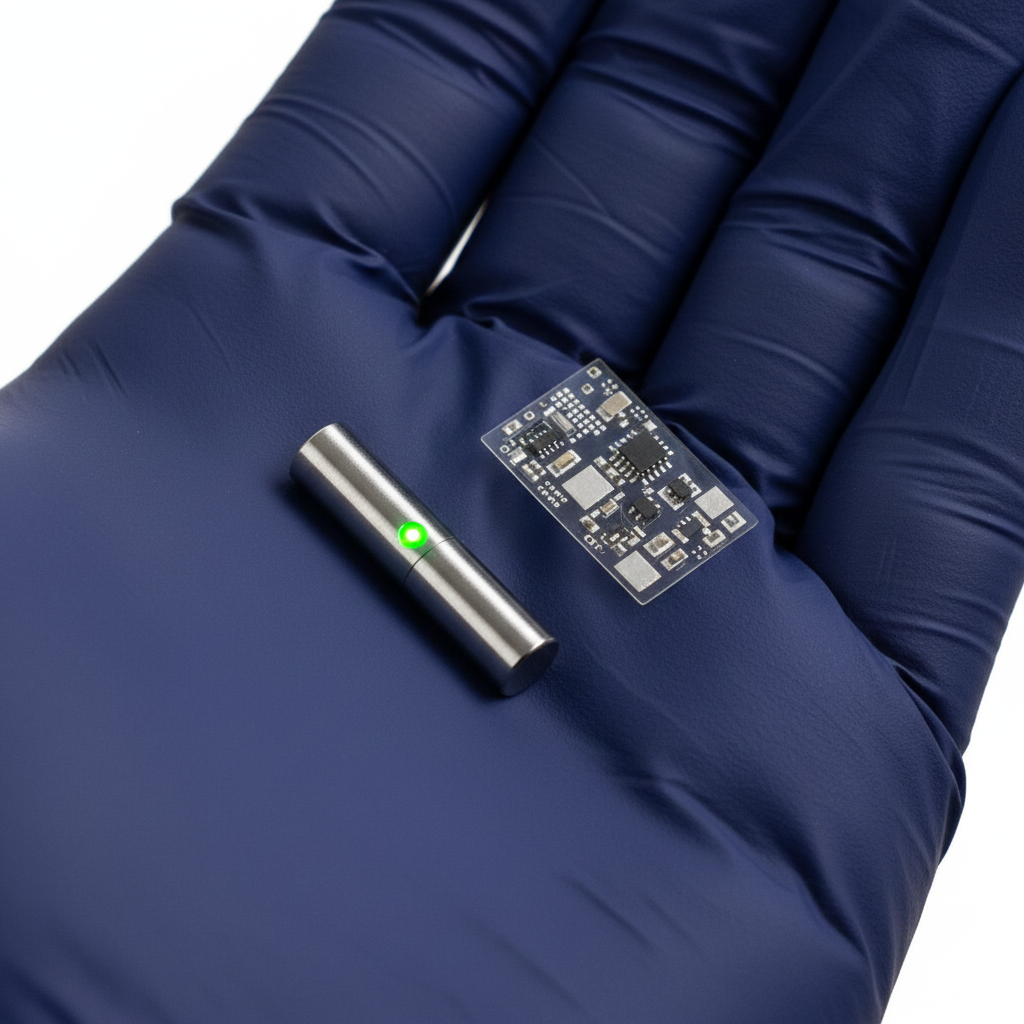

SAENSA build electronic noses, smart sensing nodes that “smell” what’s happening inside micro-environments — from packaging to confined spaces.

Powered by brain-inspired Spiking Neural Networks (SNN), our models detect early changes and flag risks before they become problems in real time.

-

SMART SENSING

Multi-parameter gas & environment sensing

Our nodes measure key variables such as VOCs, CO₂, O₂, VSCs, etilen, humidity, temperature and so on, providing a rich fingerprint of the product’s environment.

-

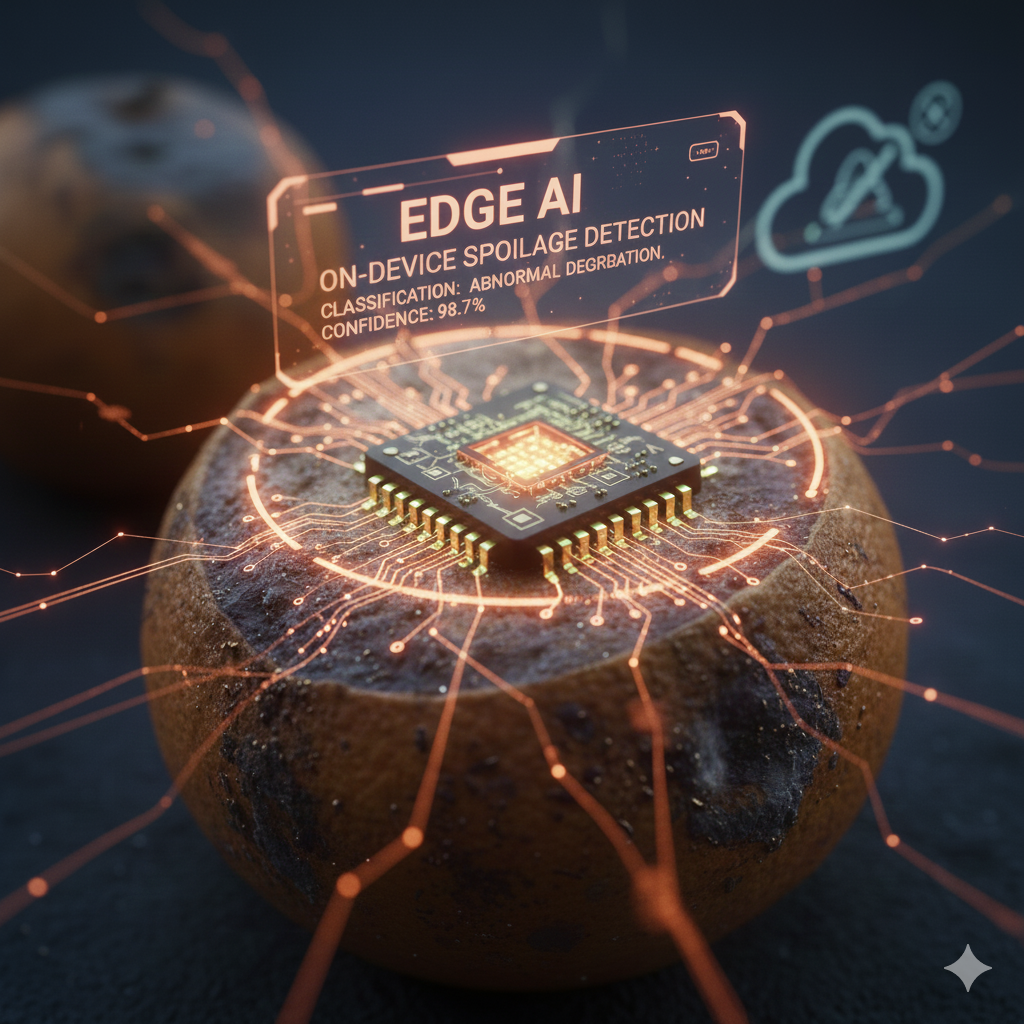

EDGE AI

On-device quality detection

Local machine learning models classify degradation patterns on the node itself, reducing latency, bandwidth needs and dependence on the cloud.

-

FOOD LOGISTICS

Designed for real supply chains

Saensa focuses on perishable food transport and storage, enabling visibility, predictive decisions and waste reduction across the supply chain.

-

SIZE & MATERIALS

CUSTOMIZED TECHNOLOGY

Our sensors can be manufactured in whatever shapes are required to address our clients’ challenges, and we can select the most suitable materials to meet each application’s demands. We produce rigid sensors, flexible sensors and hybrid forms, ensuring optimal fit, durability and performance for installation constraints, product geometry and operating environments.

“Up to a significant fraction of fresh / frozen products are lost or downgraded before reaching consumers due to invisible degradation processes. Today, quality checks are often sparse, manual and reactive.

Most logistics operators see only temperature and not inside the product and specific for your companies.”

Start a Pilot

We do not sell generic off-the-shelf sensors. We engineer custom intelligence systems tailored to your specific product, packaging, and logistical challenges.

Please describe your critical pain point below (e.g., spoilage, mold detection, cold chain visibility). Our engineering team reviews every request to assess technical feasibility and pilot potential.

Your intellectual property is safe. Mutual NDAs are available upon request before technical deep-dives.