Transforming uncertainty into business guarantee

High cut costs, protect your brand, and unlock high-value R&D data with SAENSA AI.

Unlock predictive control: Beyond simple monitoring, SAENSA transforms physical uncertainty into guaranteed brand integrity and operational efficiency. Our flexible IoT and Edge AI system generates predictive intelligence across your supply chain, leading to dramatic cost reductions (by anticipating spoilage and shrinkage), solidified brand trust by minimizing claims, and quantifiable sustainability impact (reducing food waste). We provide high-value R&D data, previously inaccessible, to accelerate product innovation and validate true shelf-life potential, turning data into a powerful asset for your growth.

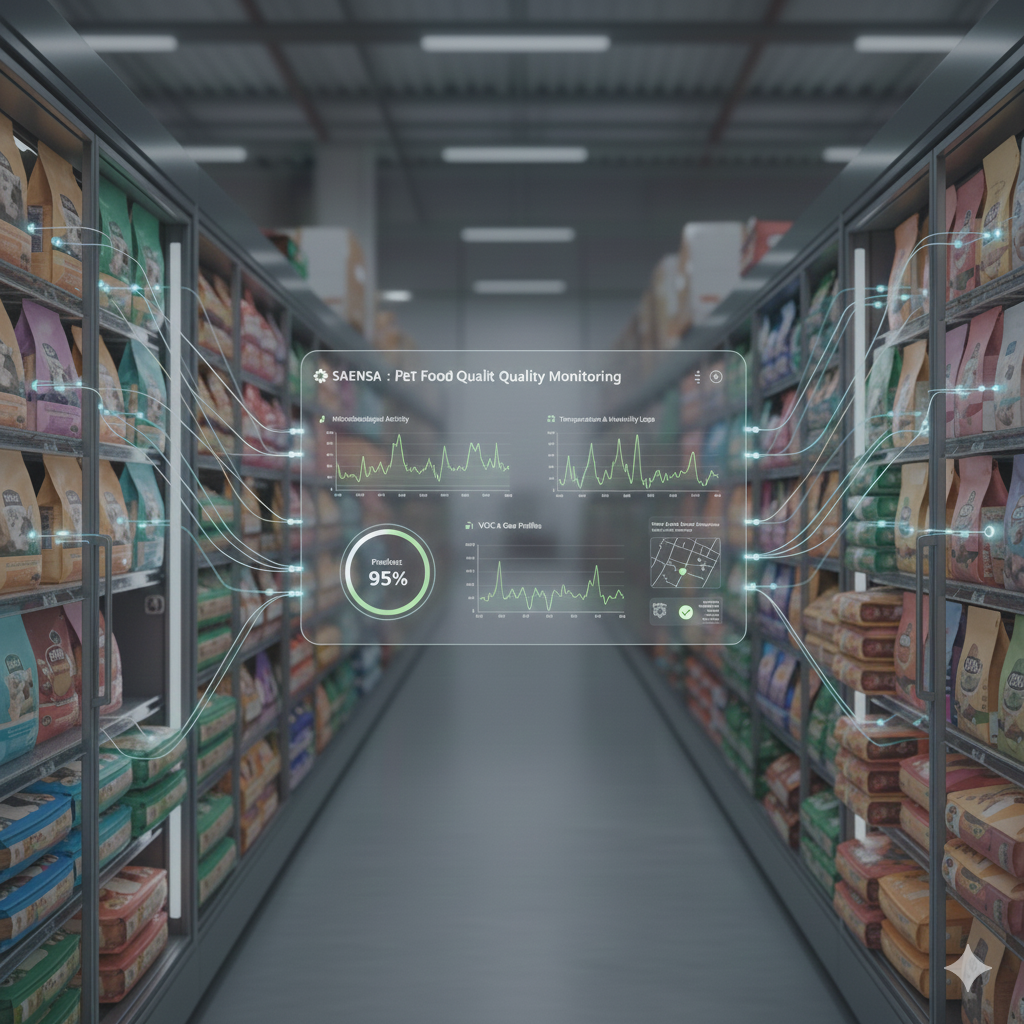

We ensure your success through a specialized co-creation model. We start with a strategic discovery meeting to understand your exact needs, followed by a customized pilot phase that validates and generates the final design ready for industrial scale. Crucially, our system delivers more than raw data: our distributed AI translates complex metrics into actionable intelligence. This is delivered via a predictive dashboard and immediate, customized reports and alerts that directly drive concrete, corrective business actions tailored to your operational requirements.

Fruit & vegetables

Monitor VOCs, temperature and gases linked to ripening and degradation in crates and pallets, helping to predict shelf life and optimize routing.

Meat & seafood

Detect volatile compounds and environmental conditions associated with early spoilage in meat and fish products during transport and storage.

Dairy, oil & ready to eat

Track micro-environment inside packaging and along the cold chain, complementing temperature logs with direct quality-related signals.

Petfood

Monitor microbiology activity, gases, temperature and so on logs with direct quality-related signals.

Start a Pilot

We do not sell generic off-the-shelf sensors. We engineer custom intelligence systems tailored to your specific product, packaging, and logistical challenges.

Please describe your critical pain point below (e.g., spoilage, mold detection, cold chain visibility). Our engineering team reviews every request to assess technical feasibility and pilot potential.

Your intellectual property is safe. Mutual NDAs are available upon request before technical deep-dives.